Joining Forces

The NNOW group was founded in 2010 with the objective of “supporting the ambitions of the business world in Northern Netherlands that is or plans to be active in the offshore wind industry by joining forces as businesses, knowledge institutes and government bodies.”

The NNOW group strives to be seen as a professional organization that is considered a full partner by energy companies and large wind clusters in Europe. Therefore it is essential that the cluster’s member companies are clear about the existing Unique Selling Points (USP) and the USPs that are missing from the group. Ultimately, the input from NNOW’s members will determine the niche of the offshore wind industry that allows the cluster to stand out.

Supply Chain in three phases

In order to answer this question it is important to position the member companies of the NNOW cluster in the offshore wind market. The offshore wind supply chain can be subdivided into three phases:

Extra: Dismantling

Finally, there is the dismantling phase, which is the construction phase in reverse order, and which will use the same companies as those of the construction phase.

1. Development

During this phase, a study is carried out into the feasibility and attractiveness of constructing an offshore wind park at a certain site. This includes measuring wind and wave data, soil surveys and environmental impact studies, engineering, providing technical, legal, financial and contractual advice.

2. Construction

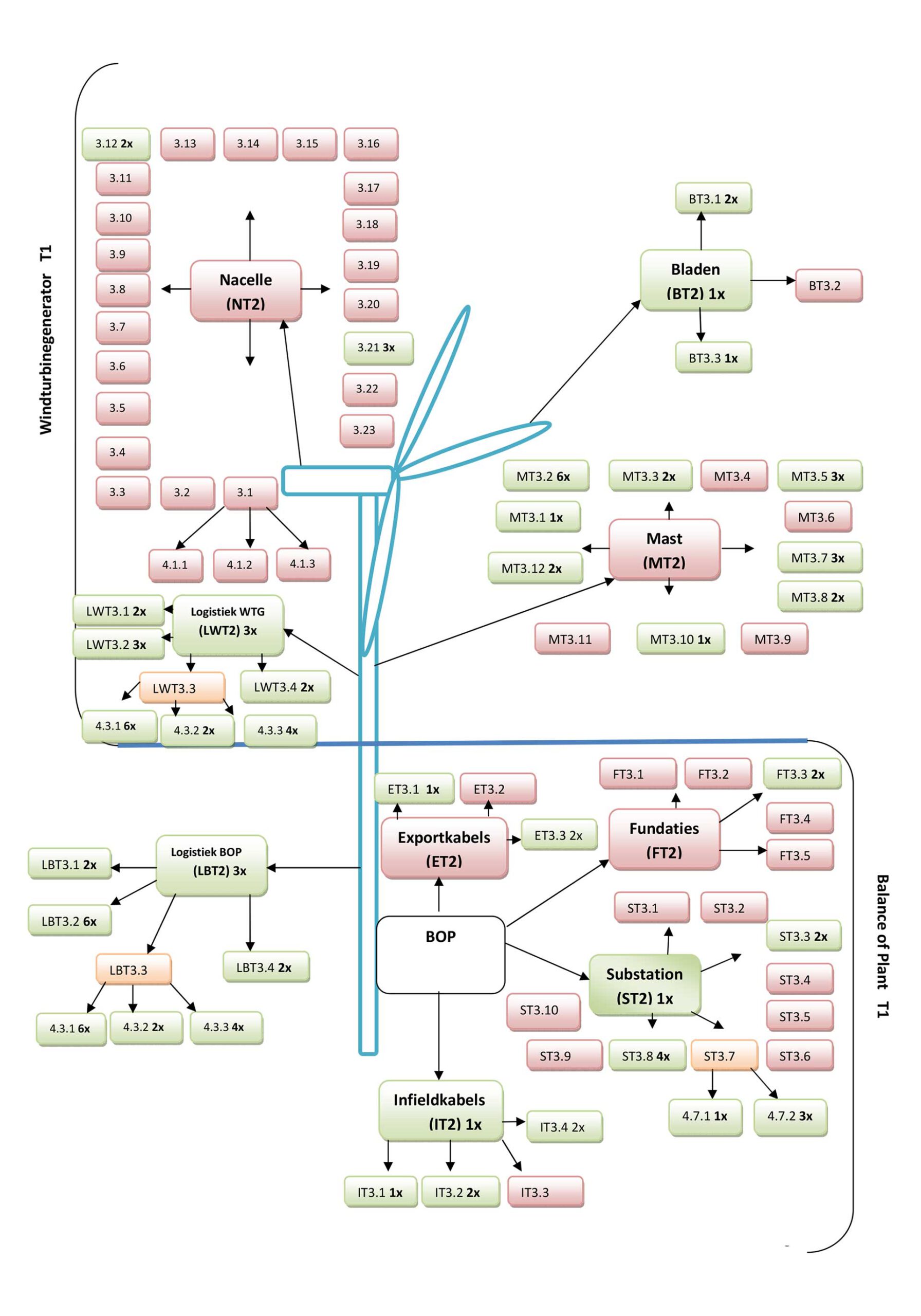

windturbinegenerator and balance of plant

To construct an offshore wind park you need wind-turbine generators and the balance of plant. The wind-turbine generator converts the flow energy of the air, i.e. the wind, into electric energy. The balance of plant consists of the remaining systems and components that are required to construct an offshore wind park, such as foundations, cables, a substation, and fitting all the components.

3. Operation and Maintenance

At this stage, the offshore wind park is operational and maintenance must be carried out, for example regular inspections of the turbines, under-water inspection of foundations and cables and replacing parts of the turbines.

The NNOW Supply Chain

For each phase the supply chain is divided into “tiers”. Manufacturers belong to the first tier and suppliers come within the second, third or fourth tier. A company that is in the second tier supplies directly to a manufacturer; if a company is in the third or fourth tier, it supplies to a supplier of the manufacturer.

Every element of the tier has been designated and/or coded. Activities that fall under the second tier of the supply chain are designated and coded, whilst those from the third and fourth tier are only coded. The key to the coding is found on page 6 and further.

Finally, every element of every tier has been given a color. The color denotes whether the activities from the tier can be carried out by a company that is part of the NNOW cluster. The figure and the mark x indicate how many companies can carry out these activities.

Green = The color green means that the activities can be carried out by a company from the NNOW cluster.

Red = The color red indicates that none of the member companies is active in this tier.

Orange = The NNOW cluster does carry out activities in the tier, but is unable to serve the tier fully.